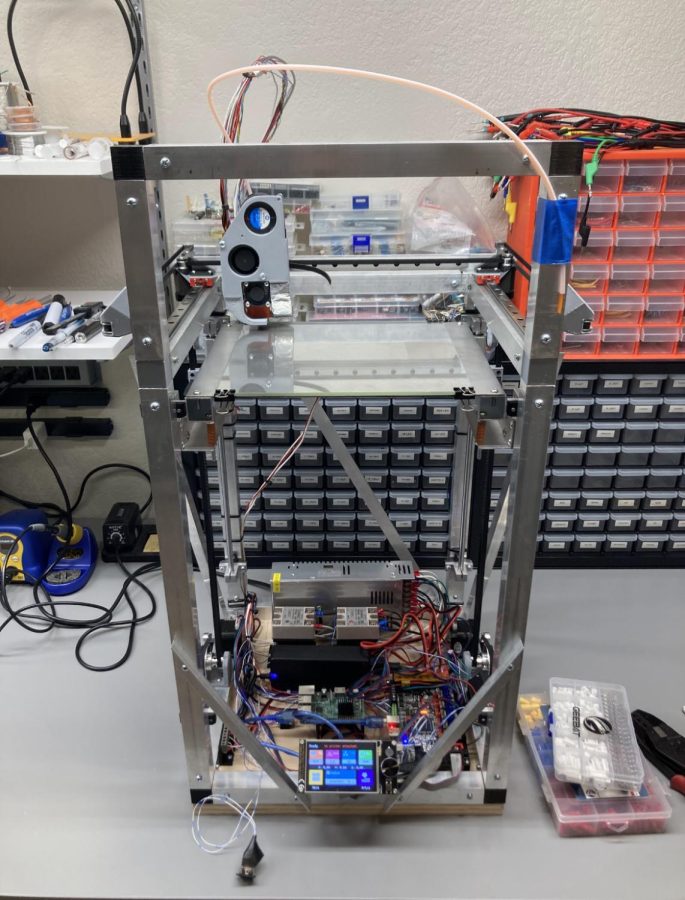

Junior designs and constructs a homemade 3D printer

Photo courtesy of Lucas Knoepfle

LIGHTING UP: This handmade 3D printer is fully wired to create a variety of objects. Knoepfle worked over the course of nine months in order to perfect his fully functioning machine, and plans to continue building on to it as the school year continues.

October 10, 2022

The snap, crackle, and pop of pristine electricity echoes through Bowie junior Lucas Knoepfle’s bedroom computer lab as he adds the finishing touches to his latest engineering project.

First, beginning the challenging project of creating a homemade, fully functioning 3D printer in October of 2021. It took Knoepfle nine strenuous months to get the printer functional. Although it is now operable, Knoepfle is determined to assemble a more advanced printer.

“I’m very close to being finished. It’s functional but there are things that need to be refined a little bit,” Knoepfle said. “It’s like a cake but without the decorative frosting yet.”

Using this mindset, Knoepfle has spent this past summer fine tuning the last few details. An aspiring electrical engineer, Knoepfle is enrolled in an engineering course here at Bowie called Engineering Design and Problem Solving, which is taught CTE teacher Christopher Redmond.

“Lucas came to class with a healthy amount of information already,” Redmond said. “He knew a lot going into class. I helped him sort of refine his knowledge and focus it a little bit more, figuring out how to design parts for customers.”

Before joining the engineering community here on campus, Knoepfle had spent years digesting as much electrical and mathematical content that he had access to.

”Almost everything I’ve learned has been through reading books and articles, watching videos, visiting online forums, and a lot of it is just trying to figure stuff out, which oftentimes means looking up whatever I need to know,” Knoepfle said. “Some examples of resources where I learned from are: the EEV blog forum and YouTube channel, college electrical engineering books, data sheets, websites that offer information on keysight technology, electronic subreddits, and YouTube channels Great Scott and Marco Reps.”

Utilizing his background knowledge and experimenting through trial and error, Knoepfle has been able to fix his own electronics, such as the occasional broken MacBook, radio, or lawnmower. Recently he has begun to build his own items from scratch. His free time is often spent troubleshooting ancient radios and adding to his growing assortment of work-in-progress machinery.

“I’ve only started doing larger projects in the last two or three years,” Knoepfle said. “But besides the printer my most notable projects have been: an RC car I built almost entirely from scratch for a competition during COVID, a work in progress 3D printed self-driving car, a simple binary calculator, I manufactured a small power control panel, and I built an antenna tower which could rotate in our backyard.”

Always looking for more complex projects to add to his collection, he desired a more challenging assignment. After purchasing his own 3D printer in December of 2020, he was able to observe how it functioned and was confident he could recreate his own.

“I’ve seen how good printers are that other people have built, and I wanted a better printer so I can compete in the 3DBenchy SpeedBoatRace challenge,” Knoepfle said, “The 3DBenchy SpeedBoatRace is where you try to print a specific little boat as fast as possible, following certain rules.”

Once the printer was functional, he was able to begin printing items for other people. Bowie junior Joab Astran met Knoepfle in an Intro to Engineering and Design class, and discovered Knoepfle had manufactured his own 3D printer. From there, Knoepfle’s printing business began. Astran is just one of a handful of students to reach out to Lucas asking for 3D printed items.

“I bought a helmet for a certain character from a show,” Astran said. “It was very well worth it. The item is high quality, feels durable and has very fine detail.”

In order to print objects, Lucas uses a free modeling application called Fusion 360 to design items prior to printing. Applications like Fusion 360 are critical for the printing process to work, because the design created in Fusion 360 (or a similar application) is what the printer’s mechanics will follow during the actual printing timespan.

“Some parts will take me four hours to design and an hour to print,” Knoepfle says, “Whereas some parts will take an hour to design and five hours to print.”

Once the item has been designed in Fusion 360, the printer uses that pre-designed model to create numerous layers of melted plastic stacked on top of each other until it produces the requirements Knoepfle programs it to meet. Redmond is especially impressed with Knoepfle.

“Lucas went beyond just creating a 3D printer by trying to push the boundaries of what these printers are even capable of by using an experimental and not fully refined geometry,” Redmond said. “So it’s impressive because it’s a 3D printer and they’re really cool. But it’s definitely impressive that it was a type of printer that is not yet fully embraced by the community.”

Redmond urges his students to seek out engineering opportunities beyond their 90 minute class period. Although there is not a specific item he’d like to see his students create, he hopes each of his students will put their engineering knowledge to good use outside of the classroom.

“There’s a lot of open endedness to the assignments themselves,” Redmond said. “So, they could go above and beyond and create new aspects of each project that are more impressive. If I’m asking for some base level creation they can make it as complex or all encompassing as they want.”

Hoping to major in electrical engineering or astrophysics, many of Knoepfle’s peers are curious as to what Knoepfle will achieve in the approaching years. Redmond specifically has high hopes for his star pupil.

“I think the next step for Lucas is a collegiate program,” Redmond says. “I expect to see some really cool things coming out of that young mind in the future, no matter what school he attends.”